Tumble Belt Shot Blasting Machine

Tumble Belt Shot Blasting Machine

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

The tumble belt shot blasting machine can be used to remove sand and rust from cast, forged and welded parts as well as aluminum and other non-ferrous parts. This series is especially effective for hard-to-clean parts, non-fragile parts,and non-core castings. The tumble belt will form a similar rotary drum and make products rotation in shot

blasting machine during blasting. It is a good way to choose this kind of equipment to clean batch of medium and small parts.

The addition of auto feeding system and continuous conveyor allows for increased production rates when used as part of a production line.

◆ Specifications

| TUMBLE BELT SHOT BLASTING MACHINE | |||||

| Model | KLQ324 | KLQ326 | KLQ3210 | KLQ3210A-1 | KLQ3212A-2 |

| Productivity(t/h) | 0.2~0.5 | 0.6~1.2 | 3~5 | 3~5 | 8~10 |

| Max Loading(kg) | 100 | 200 | 600 | 600 | 1000 |

| Max weight per (kg) | 10 | 10 | 30 | 30 | 30 |

| Diameter of Tumble Belt(mm) | φ400 | φ650 | φ1000 | φ1000 | Φ1200 |

| Volume of Tumble Belt(cbm) | 0.07 | 0.15 | 0.4 | 0.4 | 0.5 |

| Blasting Volume (kg/min) | 90 | 150 | 200 | 250 | 250×2 |

| Auto Loading Power(kw) | / | / | / | 3 | 5.5 |

◆ Advantages

● High-efficiency cleaning: The roller conveyor system enables shot peening machines to quickly and evenly remove impurities from workpiece surfaces, improving cleaning efficiency and making them suitable for mass production.

● Uniform treatment: The rotation of the roller conveyor ensures that every surface of the workpiece receives uniform blasting, guaranteeing consistent cleaning results and making it suitable for processing workpieces with complex shapes.

● Energy saving and environmental protection: The abrasive can be reused, reducing resource waste and eliminating reliance on chemical cleaning agents, meeting environmental standards and lowering operating costs.

● Improved adhesion: The uniform surface roughness after shot peening promotes the adhesion of coatings, paints, and anti-corrosion materials, enhancing the durability of the workpiece.

● Automated operation: The equipment's automated control system simplifies the operation process, improves production efficiency, and ensures the stability of the cleaning effect.

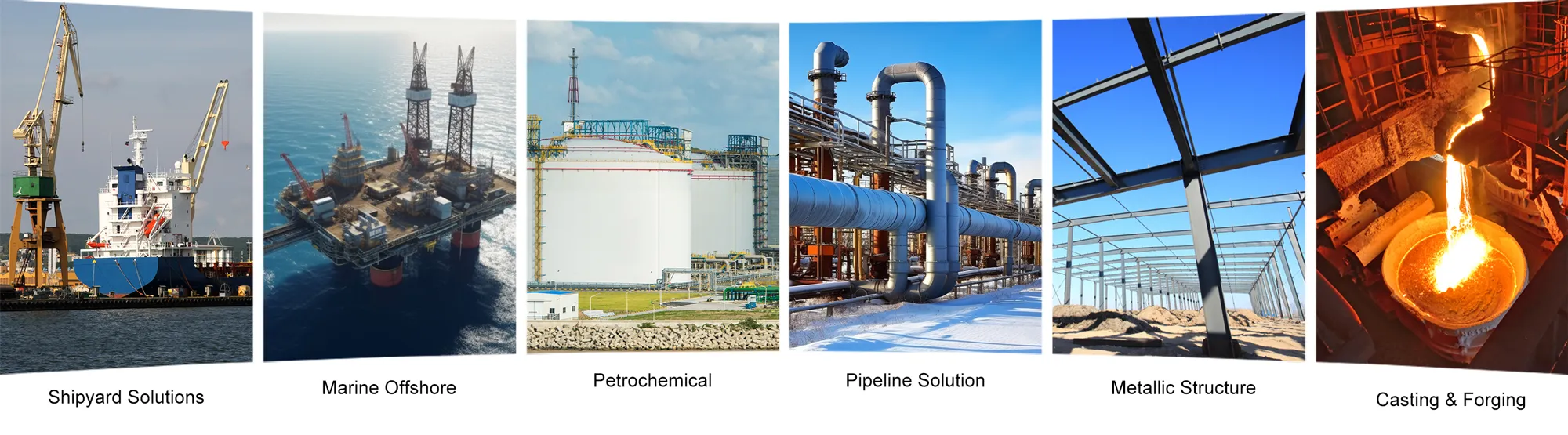

◆ Industry

◆ FAQ

What types of workpieces are suitable for a tumble belt shot blasting machine?

Tumble belt shot blasting machines are suitable for various metal workpieces, especially small or medium-sized batch production of automotive parts, mechanical parts, castings, and forgings. They are suitable for workpieces of different shapes and materials.

How to improve the working efficiency of a tumble belt shot blasting machine?

The key to improving efficiency lies in properly adjusting the spraying speed and abrasive particle size to ensure uniform spraying and no abrasive waste. In addition, regularly check the equipment and abrasive quality to ensure a highly efficient and stable shot blasting process.

What safety precautions should be taken when using a tumble belt shot blasting machine?

Wear protective glasses, earmuffs, and a dust mask during operation to avoid abrasive splashing. Regularly check the equipment's electrical system, spraying device, and abrasive to ensure safe and stable operation.

As the specialist in blasting & painting engineering area, Kholee Blast, Kholee Industrial Technology Yancheng Co., Ltd, devotes itself in providing better design and products for our client in surface finishing industry all over the world.

Kholee Blast provides a 'one-stop convenient shopping' for all your surface finishing requirements, shot blasting (wheel blasting), sand blasting machines, blasting and painting booths, painting production line, Vacuum Recovery machine, Air Cooled Dehumidifier, dust collectors and blasting abrasives etc. Besides engaging in the business of blasting equipment and accessories, Kholee Blast also distributes airless paint sprayer, air compressor and UHP water jetting with partners as understanding the client's requirements.

These products are widely used in the industries of shipyard, marine offshore, oil & gas tank, earthwork construction machinery, steel structures, castings, forgings, automotive engineering and heat treatment etc.

Thanks to KHOLEE BLAST experienced technical team, quality, cost-effectiveness and efficiency have already been considered even at the very beginning of product development.

KHOLEE BLAST, a firm and reliable partner. Take on us!

Português

Português

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)