Steel Plate Shot Blasting Machine

Steel Plate Shot Blasting Machine

Steel plate shot blasting machine is used to clean steel plate, small size of beam, pipe, angle steel etc.

Steel plate shot blasting machines are designed for cleaning steel plates, as well as small-sized beams, pipes, angle steel and similar profiles. Utilizing an advanced blast wheels, they performs thorough surface treatment by removing rust, oxide layers, and welding slag. After blasting, the steel achieves a clean Sa2.5 surface quality with a defined roughness, enhancing paint film adhesion, fatigue resistance, and corrosion protection—thereby extending the service life of the steel material.

◆ Application

Shipbuilding | Marine Offshore | Engineering Machinery | Pressure Vessel Machinery | Bridge Construction | Oil & Gas Tank Fabrication

◆ Specifications

| STEEL PLATE SHOT BLASTING MACHINE | ||||

| Model | KLB1500-4 | KLB2000-6 | KLB2500-6 | KLB3000-8 |

| Steel Plate Size (mm) Thick×Width×Length |

(4~20)×1500 ×12000 |

(4~40)×2000 ×12000 |

(4~40)×2500 ×12000 |

(4~40)×3000 ×12000 |

|

Working Speed (m/min) |

0.5~3.0 | |||

|

Loading Capacity (t/m) |

1.0 | 1.5 | ||

|

Blast Wheel (kg/min) |

290×4 | 250×6 | 350×6 | 290×8 |

|

Abrasive Recycle (t/h) |

70 | 90 | 130 | 140 |

| Abrasive Clean Off | Scraper+Screw Conveyor+Roller Brush + High Pressure Air Fan | |||

|

Dust Fume Control (m3/hr) |

25600 | 25600 | 33600 | 39000 |

| Dust Collector | Pulse Jet Dust Collector | |||

|

Surface Quality After Blasting |

Sa 2.5 GB8923-88(ISO8501) | |||

|

Roughness After Blasting (μm) |

Ra20~75 | |||

|

Dust Emission Density (mg/m³) |

30 | |||

| Noise Level (dB) | ≤85 | |||

| STEEL PLATE SHOT BLASTING MACHINE | ||||

| Model | KLB3500-8 | KLB4000-8 | KLB4500-10 | KLB5000-10 |

| Steel Plate Size (mm) Thick×Width×Length |

(4~60)×3500 ×12000 |

(4~60)×4000 ×12000 |

(4~60)×4500 ×12000 |

(4~60)×5000 ×12000 |

|

Working Speed (m/min) |

0.5~3.0 | |||

|

Loading Capacity (t/m) |

2.0 | 2.5 | ||

|

Blast Wheel (kg/min) |

350×8 | 480×8 | 480×10 | 480×10 |

|

Abrasive Recycle (t/h) |

170 | 240 | 300 | 300 |

| Abrasive Clean Off | Scraper+Screw Conveyor+Roller Brush+High Pressure Air Fan | |||

|

Dust Fume Control (m3/hr) |

42500 | 42500 | 48500 | 48500 |

| Dust Collector | Pulse Jet Dust Collector | |||

|

Surface Quality After |

Sa 2.5 GB8923-88(ISO8501) | |||

|

Roughness After Blasting (μm) |

Ra20~75 | |||

|

Dust Emission Density (mg/m³) |

30 | |||

| Noise Level (dB) | ≤85 | |||

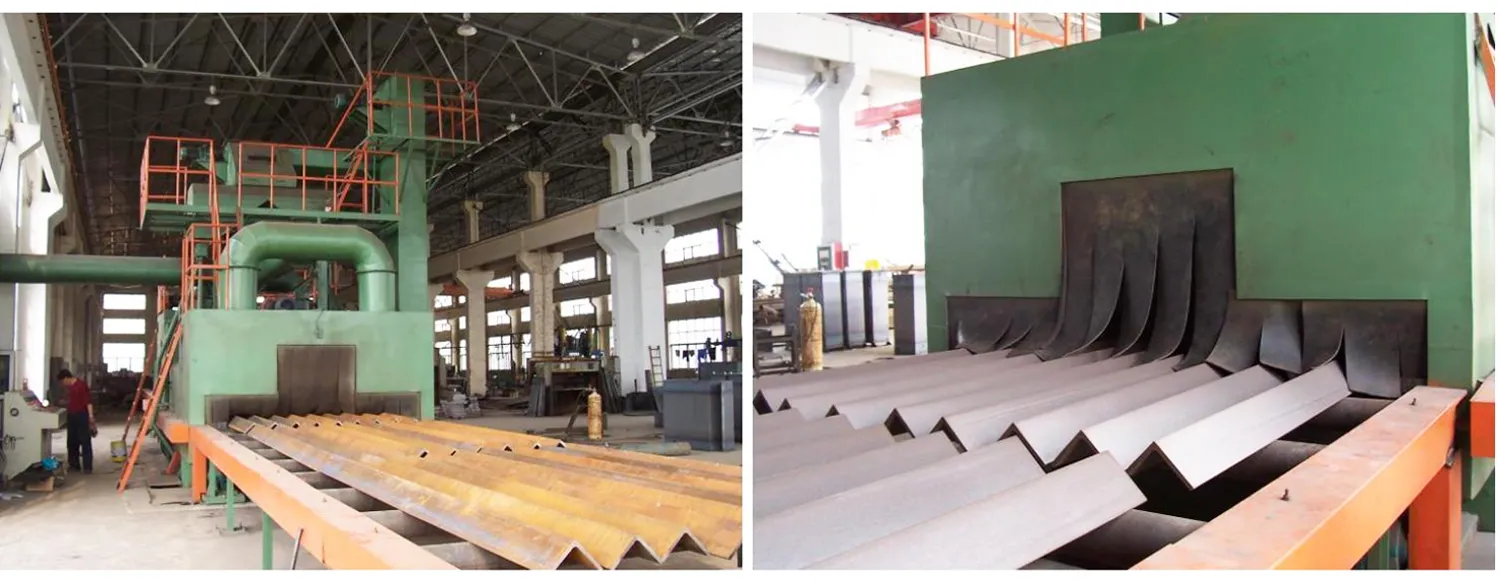

◆ Case Showcase

◆ Advantages

● High-efficiency cleaning: shot blasting machines can quickly remove rust, scale, and other impurities from steel plate surfaces, significantly improving cleaning efficiency and making them suitable for mass production.

● Uniform treatment: the shot blasting process is uniform, ensuring thorough cleaning of the steel plate surface and achieving consistent quality standards.

● Enhanced adhesion: after shot blasting, the steel plate surface develops a suitable roughness, enhancing the adhesion of subsequent coatings, paints, or anti-corrosion materials.

● Environmentally friendly and energy-saving: the equipment adopts a high-efficiency dust fume control system, reducing dust emission produced by blasting to maxium and avoiding the use of harmful chemicals to clean metal surface, meeting environmental standards.

● Automated control: The automated system adopts PLC automatic control , reduces manual intervention, improves production efficiency, and ensures consistent cleaning results.

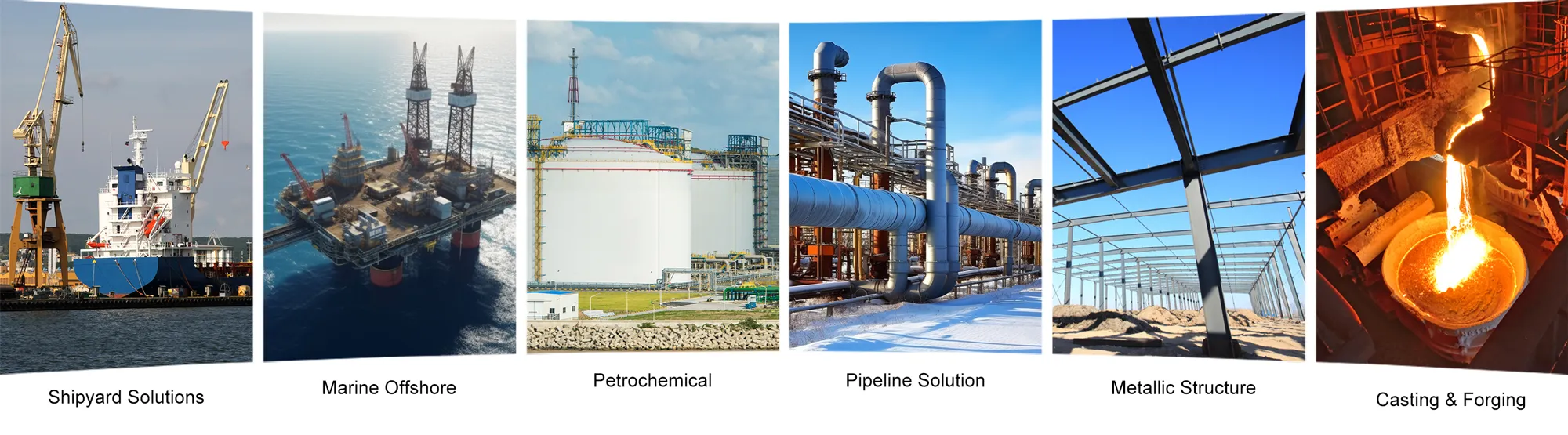

◆ Industry

◆ FAQ

Q: How do I know if your shot blasting machine is suitable for my products?

A: To ensure we recommend the most effective solution, please provide the following details about your application. The more information you share, the more accurate our proposal will be.

Q: What kind of products do you need to do blasting?

A: Steel Plate, steel structures, pipes, automotive parts, forged gears, structural steel, precision castings, sand casting etc

Q: Primary Purpose: What is the main goal of shot blasting?

A: Surface Cleaning: Remove rust, mill scale, oxide layers, old paint, or welding slag

Surface Preparation: coating, plating, or painting adhesion.

Deburring/Deflashing: Remove burrs from machined or stamped parts, aluminium parts .

Descaling: Remove heat-treated scale or casting sand, investment casting shell.

Peening: Improve fatigue strength (stress relief).

Aesthetic Finishing: Create a uniform matte or textured surface.

Q: What is your products Specifications

A: Maximum Workpiece: Length x Width x Height and Weight

Minimum Workpiece: Length x Width x Height and Weight

Typical Batch Size/Throughput: How many parts do you process per hour or per shift?

Q: Performance & Requirements

Q: Required Cleaning Efficiency (e.g., Sa 2.5, or describe the desired cleanliness)

Q: Current Production Method: How are you currently cleaning or preparing these surfaces?

Q: Future Considerations: Do you anticipate changes in product size or volume?

As the specialist in blasting & painting engineering area, Kholee Blast, Kholee Industrial Technology Yancheng Co., Ltd, devotes itself in providing better design and products for our client in surface finishing industry all over the world.

Kholee Blast provides a 'one-stop convenient shopping' for all your surface finishing requirements, shot blasting (wheel blasting), sand blasting machines, blasting and painting booths, painting production line, Vacuum Recovery machine, Air Cooled Dehumidifier, dust collectors and blasting abrasives etc. Besides engaging in the business of blasting equipment and accessories, Kholee Blast also distributes airless paint sprayer, air compressor and UHP water jetting with partners as understanding the client's requirements.

These products are widely used in the industries of shipyard, marine offshore, oil & gas tank, earthwork construction machinery, steel structures, castings, forgings, automotive engineering and heat treatment etc.

Thanks to KHOLEE BLAST experienced technical team, quality, cost-effectiveness and efficiency have already been considered even at the very beginning of product development.

KHOLEE BLAST, a firm and reliable partner. Take on us!

Português

Português