Portable Shot Blaster

Portable shot blaster | Concrete Floor blaster | Road blaster is used to mainly used for road construction, maintenance, bridge. Shot blasting technology is widely used in bridge anti-corrosion, road roughening, removing road marks, clean paint film and rust fromsteel plateetc. During blasting, thewholeprocessis ofno dust,movable,high productivity.

- For concrete: Road blaster | concrete floor shot blaster is used to remove impurity and laitance layer on concrete; also it can roughen the concrete and make the surface uniform roughness which can improve the adhesive force between water prooflayer and concrete layer; also it can make the crack of concrete show completely.

- For steel: Before primer painting to steel plate in steel bridge or oil tank, it must do blasting to clean the surface of steel.By shot blasting, the surface quality of steel can reach sa2.5/sa3.0 and get certain roughness, which can meet the requirements of coating. The whole blasting process is of no dust and easymove.

◆ Working Principle:

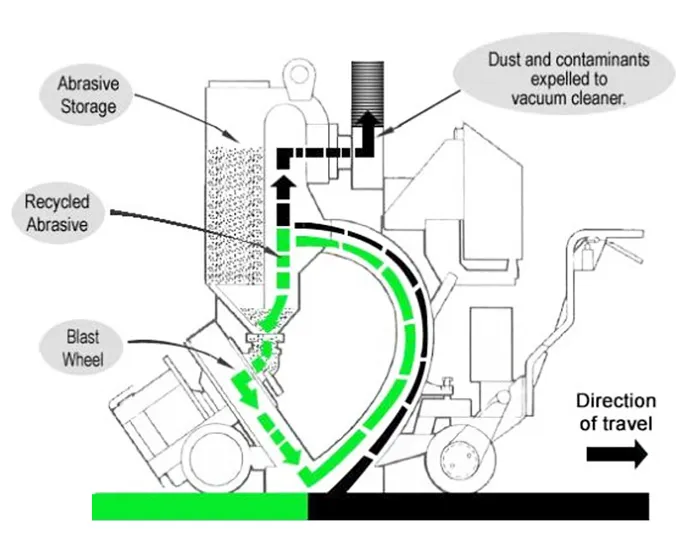

The blasting turbine on mobile road blaster | concrete floor shot blaster will through steel shots to hit the surface of concrete or steel plate. The mixture of steel shots, dust and other impurity will rebound via rebound tube to separator. The separator will separate the steel shots and dust, impurity via dust removing system. Qualified steel shots will be fallen into storage bin for recycle again. Dust and impurity will go with air todust collector.

The shot blaster is equipped with dust removing system. During blasting process, it can reach no dust and no pollution which not only improves productivity but also protects environments.

◆ Application

- Improve the roughness and friction factor of asphalt pavement to improve adhesive force of road and guarantee safety of driving.

- To do blasting cleaning to steel structure bridge, oil tank and ship deck. After blasting, it can reach sa2.5/sa3.0 which is good for painting.

- Cleans offshore platforms, prepares petroleum and water storage tank surfaces

- Tunnel road maintenance

- Airport runway preventive maintenance: Remove tire marks of air planes, road markings, improve adhesive force, roughness and friction factor of airport runway.

- Municipal road: Remove tire marks, road markings, improve adhesive force, roughness and friction factor of municipal road.

- Floor: Cleans factory and warehouse floors, prepares parking lots and garage decks

◆ Advantage

● Highly Efficient Cleaning: portable shot blaster can quickly remove rust, dirt, and oxides from metal surfaces, suitable for large-area cleaning and significantly improving work efficiency.

● Flexible Application: Due to its mobility, the equipment can be moved between different sites as needed, adapting to various cleaning tasks, especially suitable for large construction sites or different production lines.

● Enhanced Adhesion: Through shot blasting, a uniform roughness is formed on the metal surface, enhancing the adhesion of coatings or anti-corrosion layers, reducing the risk of coating peeling, and extending the material's service life.

Cost Savings: Compared to traditional cleaning methods, mobile shot blasting machines reduce labor costs and improve operational efficiency, lowering long-term maintenance and cleaning costs.

● Environmentally Friendly and Energy-Saving: Compared to chemical cleaning methods, shot blasting does not use harmful chemicals, and the abrasive can be reused, reducing waste emissions and being environmentally friendly.

◆ Specifications

| MOVABLE SHOT BLASTER丨CONCRETE FLOOR BLASTER 丨ROAD BLASTER | ||||

| Model | KLRO270 | KLRO550 | KLRO850 | KLRO1000 |

| Blasting Width | 270MM | 550MM | 850MM | 1000MM |

| Blasting Productivity | ~120M²/HR | ~400M²/HR | ~600M²/HR | ~800M²/HR |

| Moving Speed | 0.5~25M/MIN | 0.5~25M/MIN | 0.5~25M/MIN | 0.5~25M/MIN |

| Blasting Power | 11KW×1 | 11KW×2 | 15KW×2 | 18.5KW×2 |

| Moving Power | 0.75KW | |||

| Centrifugal Air Fan | 4KW | 7.5KW | ||

| Dust Collector | FILTER CARTRIDGE - PULSE JET CLEANING | |||

| Air Compressor | 3KW | |||

| Electrical Power | 380V/415V/50HZ/3PH | |||

| Outsize of Equipment | 1940×380×1100MM | 1940×720×1100MM | 2000×1000×1300MM | 2100×1250×1350MM |

| Weight of Equipment | ≤400KGS | ≤800KGS | ≤1300KGS | ≤1600KGS |

◆ FAQ

Q: How do I know if your shot blasting machine is suitable for my products?

A: To ensure we recommend the most effective solution, please provide the following details about your application. The more information you share, the more accurate our proposal will be.

Q: What kind of products do you need to do blasting?

A: Steel Plate, steel structures, pipes, automotive parts, forged gears, structural steel, precision castings, sand casting etc

Q: Primary Purpose: What is the main goal of shot blasting?

A: Surface Cleaning: Remove rust, mill scale, oxide layers, old paint, or welding slag

Surface Preparation: coating, plating, or painting adhesion.

Deburring/Deflashing: Remove burrs from machined or stamped parts, aluminium parts .

Descaling: Remove heat-treated scale or casting sand, investment casting shell.

Peening: Improve fatigue strength (stress relief).

Aesthetic Finishing: Create a uniform matte or textured surface.

Q: What is your products Specifications

A: Maximum Workpiece: Length x Width x Height and Weight

Minimum Workpiece: Length x Width x Height and Weight

Typical Batch Size/Throughput: How many parts do you process per hour or per shift?

Q: Performance & Requirements

Q: Required Cleaning Efficiency (e.g., Sa 2.5, or describe the desired cleanliness)

Q: Current Production Method: How are you currently cleaning or preparing these surfaces?

Q: Future Considerations: Do you anticipate changes in product size or volume?

As the specialist in blasting & painting engineering area, Kholee Blast, Kholee Industrial Technology Yancheng Co., Ltd, devotes itself in providing better design and products for our client in surface finishing industry all over the world.

Kholee Blast provides a 'one-stop convenient shopping' for all your surface finishing requirements, shot blasting (wheel blasting), sand blasting machines, blasting and painting booths, painting production line, Vacuum Recovery machine, Air Cooled Dehumidifier, dust collectors and blasting abrasives etc. Besides engaging in the business of blasting equipment and accessories, Kholee Blast also distributes airless paint sprayer, air compressor and UHP water jetting with partners as understanding the client's requirements.

These products are widely used in the industries of shipyard, marine offshore, oil & gas tank, earthwork construction machinery, steel structures, castings, forgings, automotive engineering and heat treatment etc.

Thanks to KHOLEE BLAST experienced technical team, quality, cost-effectiveness and efficiency have already been considered even at the very beginning of product development.

KHOLEE BLAST, a firm and reliable partner. Take on us!

Português

Português