KL-VR-90WD Abrasive Vacuum Recovery System

KL-VR-90WD Abrasive Vacuum Recovery System

KL-VR-90WD vacuum recovery system not only is used to recovery dry abrasives after blasting for ship, tanks, but also used to suck wet abrasives and mud. The equipment structure, working principle and powerconsumptionisas following:

- The whole system is made of vacuum pump, motor, dust collector, water separating unit, electrical control andabrasive storage silo etc.

- The vacuum pumpdriven by motor will produce high negative pressure to suck blasting abrasives, water, oil, mud. Then these materials will enter abrasive storage silo via hose. Then dust separating, water & vapor separating then abrasive recycle finished. During abrasive suction, water suction or mud suction, in order to reduce dust and water into vacuum pump, the system is equipped with cyclone dust collector, waterseparator, pulse jet dust collector.

◆ Specifications

| Model | KL-VR-90 Portable Abrasive Vacuum Recovery System |

| Electrical Power | 380V/415V/440V, 50Hz/60Hz, 3Ph |

| Electrical Motor IP55, Class F |

90kw Star Delta |

| Air Flow | 60m3/min @-450mmHg |

| Max Vacuum Degree | -0.0667Mpa Over vacuum protection by vacuum relief valve |

| Vacuum Pump | KFM Korea | ANLET Japan |

| Dust Collector | PLC control Pulse Jet Clean Type Dust Collector Periodical Air Reverse Jet |

| Compressed air | 0.6~0.8Mpa, 1.0m3/min |

| Dust Emission Density | ≤25mg/m3 |

| Electrical Control | Schneider & Siemens PLC, IP54 Protection: Phase Stage | Over & Low Voltage | Overloading | Wrong Phase |Dust Level etc |

| Noise Level | ≤85dB(A) @ Radius 5m |

| Equipment Size | 2.9×2.2×2.4 mtr |

| Grit hose Size | 5”, 4” |

| Abrasive storage silo | Φ1700×3250mm 10 tons |

| Abrasive Recovery Capacity | 6~10 t/hr 40m vertical suction 20m horizontal Machine to silo |

| Standard Supply Scope of Equipment | - Vacuum Recovery Machine, 1 unit - Abrasive Collection Barrel,1 unit - Vacuum Hose - Grit Hose - Dust Hose - Floor Suction Tool |

◆ Advantages

● High-Efficiency Abrasive Recycling

Equipped with a large vacuum pump and high-power motor for heavy-duty continuous operation. It efficiently recovers and cleans steel grit, garnet, copper slag and other abrasives after blasting, minimizing resource wastage and significantly boosting overall blasting efficiency.

● Substantial Cost Reduction

By enabling the recycling and reuse of abrasives, the equipment drastically cuts down on abrasive procurement costs, helping enterprises achieve considerable savings in operational expenses.

● Eco-Friendly & Clean Operation

Recovered abrasives undergo thorough cleaning and filtration, effectively reducing environmental pollution and greatly improving the cleanliness of the workplace.

● User-Friendly Operation

Boasting a streamlined structural design, the equipment is incredibly easy to operate. Workers can master its use in a short time, ensuring a highly efficient and stable production process.

● Significant Labor Savings

Adopting high-pressure suction by vacuum pump, it enables long-distance conveying of used abrasives (from blasting rooms, vessel tanks, ballast tanks and other work sites) directly to the storage silo after blasting. This eliminates the need for heavy manual handling, significantly reducing labor intensity.

◆ Industry

To recovery steel shots, grits and garnet after blasting and widely used in the industry of shipbuilding, ship repair, big tank internal blasting etc.

◆ FAQ

What types of abrasives can an abrasive vacuum recovery machine handle?

An abrasive vacuum recovery machine is suitable for a variety of abrasives, such as steel shot, steel grit, aluminum grit, and ceramic particles. It is suitable for abrasive recovery in sandblasting, shot peening, and other surface treatment processes.

How to improve the recovery efficiency of an abrasive vacuum recovery machine?

Methods to improve recovery efficiency include regularly cleaning the filtration system, ensuring the vacuum pump and pipelines are unobstructed, maintaining good equipment operating condition, and ensuring the cleanliness and quality of the abrasive.

What safety precautions should be taken when using an abrasive vacuum recovery machine?

During operation, wear appropriate protective eyewear, earmuffs, and a dust mask to avoid inhaling fine dust. Regularly inspect the equipment's electrical system and recovery pipelines to ensure safe and reliable operation.

As the specialist in blasting & painting engineering area, Kholee Blast, Kholee Industrial Technology Yancheng Co., Ltd, devotes itself in providing better design and products for our client in surface finishing industry all over the world.

Kholee Blast provides a 'one-stop convenient shopping' for all your surface finishing requirements, shot blasting (wheel blasting), sand blasting machines, blasting and painting booths, painting production line, Vacuum Recovery machine, Air Cooled Dehumidifier, dust collectors and blasting abrasives etc. Besides engaging in the business of blasting equipment and accessories, Kholee Blast also distributes airless paint sprayer, air compressor and UHP water jetting with partners as understanding the client's requirements.

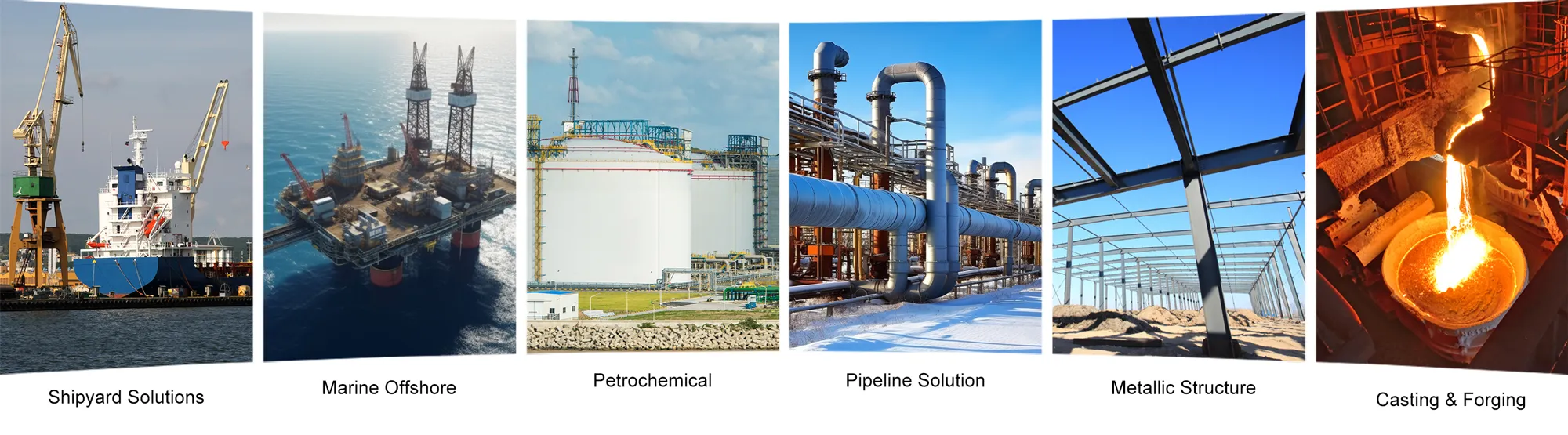

These products are widely used in the industries of shipyard, marine offshore, oil & gas tank, earthwork construction machinery, steel structures, castings, forgings, automotive engineering and heat treatment etc.

Thanks to KHOLEE BLAST experienced technical team, quality, cost-effectiveness and efficiency have already been considered even at the very beginning of product development.

KHOLEE BLAST, a firm and reliable partner. Take on us!

Português

Português